|

|

|

#1

|

||||

|

||||

|

No really.... welding and hammer forming!!

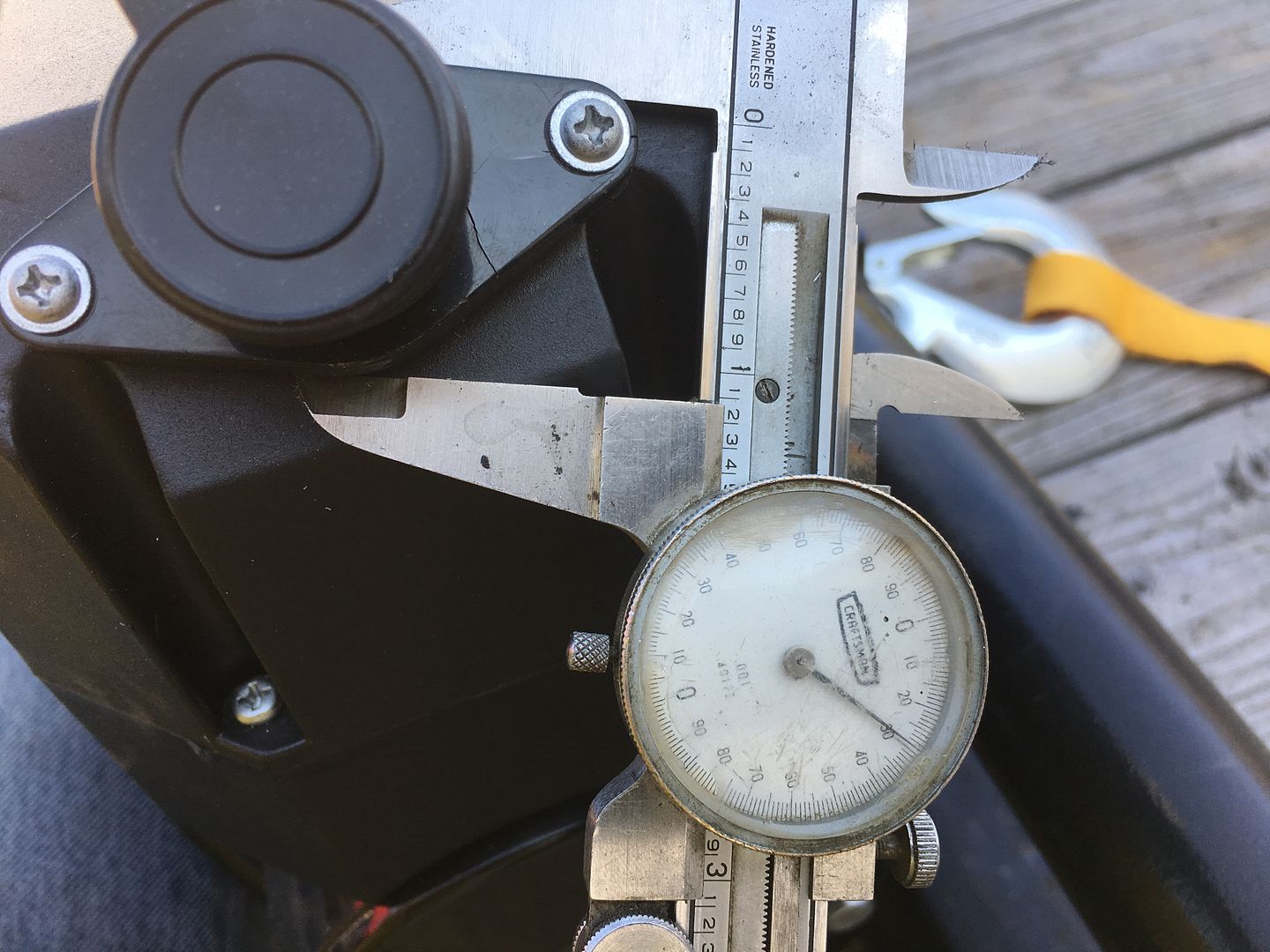

Found a shelf casualty on the new winch we bought for the car trailer, appears the box was dropped at some point or this controller connector is just garbage.  Being a Sunday with little open to fix this, lets see what we can do.. Measurements....   Trying out some plastic fusion welding using a soldering iron... we better hide that...  Used socket as a dowel pin, hammer form plates cut out of 10 gauge steel scraps.. Our cover will be made out of polished stainless for resistance to the elements.  Just resting here for the picture, but one "tab" was clamped in the vise, vise grips clamped the open side, and the flange hammered over. Pulled out, rotate, repeat. About 5 minutes later and we are done.    Installed...   That should hold us.. .

__________________

Robert Instagram @ mccartney_paint_and_custom McCartney Paint and Custom YouTube channel |

| Thread Tools | Search this Thread |

| Display Modes | |

|

|