|

|

|

|

|

#1

|

|||

|

|||

|

Hello, my name is Eddie and I live in Washington state. I've done some projects in the past, mostly welding (as a hobbiest, not professionally) and am looking to expand my knowledge and hopefully my skill set. I recently purchased a 20 ton hydraulic shop press with the intention of building a press brake for it. I also want to buy some dimple dies, and hopefully a entry level bead roller in the next few weeks. One of my main interest have always been older cars, I hope to learn the skills necessary so that I can start building my own inner door panels, dash instrument panel inserts, center consoles etc.

I look forward to getting to know you fellow members, and can't wait to start reading through this forum! Sincerely Eddie.

__________________

~Eddie "Failure is simply the opportunity to begin again, this time more intelligently" -Henry Ford |

|

#2

|

|||

|

|||

|

Hi Eddie welcome to the forum

Peter

__________________

P.Tommasini Metalshaping tools and dvds www.handbuilt.net.au Metalshaping clip on youtube http://www.youtube.com/watch?v=WEAh91hodPg Making Monaro Quarter panel: http://www.youtube.com/watch?v=KIpOhz0uGRM |

|

#3

|

|||

|

|||

|

Thanks for the welcome Peter! I am already enjoying the forum and and have been reading through other members threads, there is such a vast amount of knowledge to be gained here, I was astonished by some of the scratch built cars bodies some members are working on, really makes me want to learn and try new things!

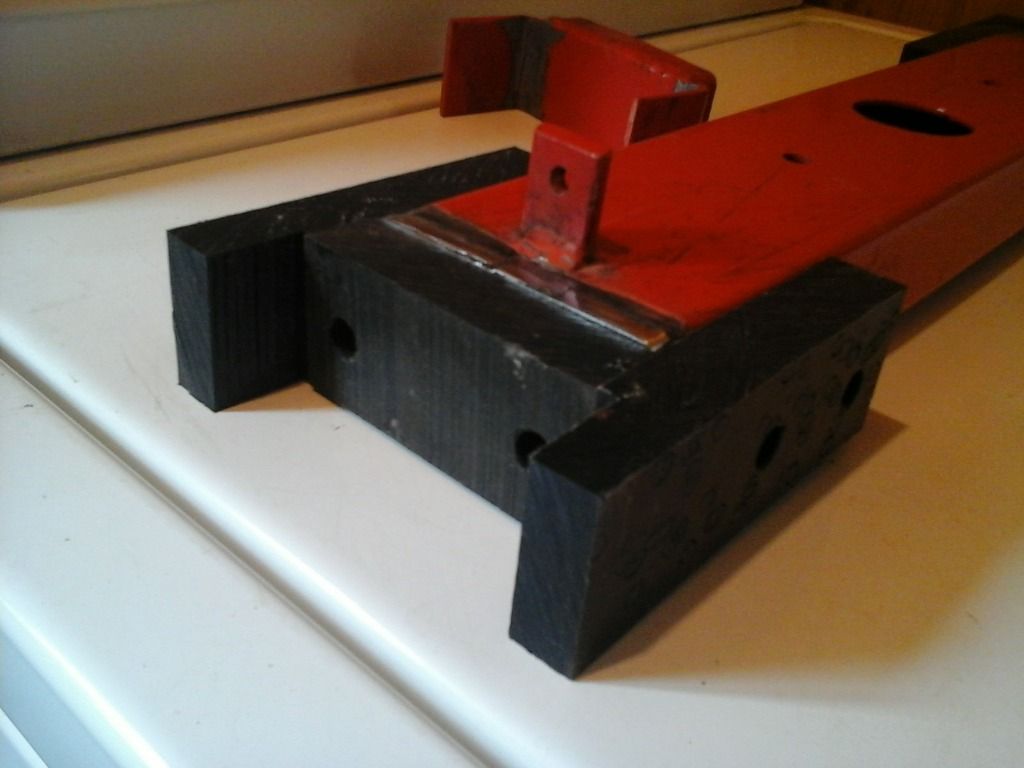

As I mentioned earlier in my introduction I recently purchased a lightly used 20 ton shop press off Craigslist. The previous owner was a retired truck driver and used it for pressing bearings, but said he only used it a few times. It looked like new so I bought it. Today I was planning on building a press brake for it so that I could make some 90° bends in some 16 gauge sheetmetal with it, but after a closer inspection decided that it had a few issues that I needed to address first. I noticed that when trying to lower the press bed it would get stuck. The lower I tried to move it the worse it got. After taking a couple measurements I found that the "H" frame tapered in 1/2" at the bottom. The inside measurement between the H frame was 18" at the top and 17-1/2" at the bottom also I noticed that the angle iron crossmember was bolted in the wrong location so I couldn't move the press bed down to the bottom 2 adjustment holes. So I unbolt ed the crossmember and moved it to the proper location down by the feet of the H frame, I also used a couple washers and squared the frame up so now it's within a 1/16 of an inch instead of a 1/2". I also made a small "T" handle for the pressure release valve, so now I don't have to use the big clumsy jack handle to release it. I also shorten the jack handle by 10" seemed way to long. My next project will be to make some gliders out of some scrap UHMW to take out some of the slack/play in the press. There is alot of play and one of the big springs seems to have more tension than the other side so it has a tendency to crook to one side instead of being square. it seems like a common problem with the lesser expensive brands. Hopefully I'll be able to start building the press brake soon! I ordered a Woodward Fab bead roller today, can't wait to get it and start practicing! From the reviews I read it sounds like its a descent entry level bead roller, do any of you have any experience with this model?  Anyway, sorry for rambling on...figured I'd go ahead and throw in a couple pics of my press, in one pic you can see where I moved the bottom crossmember down to the correct location, the other pic shows the pressure release T handle I made. Thanks for checking in!

__________________

~Eddie "Failure is simply the opportunity to begin again, this time more intelligently" -Henry Ford Last edited by Eddie_71'; 03-20-2017 at 08:23 PM. |

|

#4

|

|||

|

|||

|

Welcome to the forum, Eddie.

__________________

AC Button II http://CarolinaSculptureStudio.com https://www.youtube.com/channel/UCzSYaYdis55gE-vqifzjA6A Carolina Sculpture Studio Channel |

|

#5

|

|||

|

|||

|

I have a few newbie questions and thought I would post them here instead of starting a new thread. I have an 87' toyota 4runner (or Surf, depending on what country). The rear cargo panels that cover the inside of the truck box are made of very thin (and now 30yrs later very brittle plastic). I thought as a practice project I might attempt to remake these panels. If I were to use sheet metal (steel) what gauge would you recommend? I just received my Woodward Fab beadroller last week and the directions says it will do up to 18ga, do you think that would be OK to use? What about aluminum, what gauge would you recommend? Thanks in advance, here is a couple pics of the passenger side rear cargo side panel I'm wanting to remake. I'm still trying to figure out the best way to go about it, I was thinking of making it in 2 sections, maybe 3 and then welding them together... hopefully I'm not taking on to big of a first project!

__________________

~Eddie "Failure is simply the opportunity to begin again, this time more intelligently" -Henry Ford Last edited by Eddie_71'; 03-29-2017 at 03:36 PM. |

|

#6

|

|||

|

|||

^^^I was playing around wanting to make some dies for a press brake. Just a peice of pipe and some C channel and I was able to make this curved bend. It's real close to the contour I would need for the cargo panel pictured above. I decided that my press had to much play side to side and front to back so I built some new guides out of some UHMW to tighten it up a bit.     Then I started making a die for the press brake for 90° bends.     ^^^Here's a couple practice bends I made in some scrap 16 ga. I need to finish welding up the 90° die and paint it, then I'm going to build another one using the round pipe in the above pic for curved bends. I still need to build a stand for my Woodward Fab beadroller. I want to make some improvements to it like others have which would include: reinforcing the frame to make it more ridgid, adding a wheel to replace the crank handle, and adding a spring to raise the upper die when it is loosened. Eventually I want to add a motor and foot pedal to it. Thanks for checking in... ■Edit: I replaced the self tapping screws I used to hold the uhmw guides they were a little to short and I had one guide loosen up. Instead I drilled and tapped the holes for 1/4" - 20×1-1/4" bolts.

__________________

~Eddie "Failure is simply the opportunity to begin again, this time more intelligently" -Henry Ford Last edited by Eddie_71'; 04-10-2017 at 03:15 PM. |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|