|

|

|

#1

|

|||

|

|||

|

Hi Guys,

I'm just about to tackle making some patch repair sections for my 37 Ford but thought I should get some advise before I just start making dies for the Trumpf reciprocating machine and attempting to press them out. I am hoping to replace the existing lower 1/4 panel patch repairs. I have made some templates and am ready to start but am unsure which way to tackle the panel. Firstly I have wheeled some shape into the steel and would now like to attempt make the 'B' pillar folded sections. Can this be done simply on the Trumpf with a single die or would I need to make the folded sections detail on the 'B' pillar and then tip the final 90 degree bend where it becomes the 1/4 panel over separately? I do have an Eastwoods bead roller but do not have a tipping die, perhaps this could be an option if I were to get one sorted. Anyways any advice greatly appreciated, thanks in advance Nigel.

__________________

Nigel.M |

|

#2

|

|||

|

|||

|

Nigel

I usually make the panel first ,then I brake the lines one by one on the wheel ,when you turn the first line there is no need to shrink it over too much, because usually when you get the second line in it shrink it self. Just do a bit of adjusting on you last line Peter PS you can do it also on a Pullmax by making the right dies, or on a bead roller

__________________

P.Tommasini Metalshaping tools and dvds www.handbuilt.net.au Metalshaping clip on youtube http://www.youtube.com/watch?v=WEAh91hodPg Making Monaro Quarter panel: http://www.youtube.com/watch?v=KIpOhz0uGRM Last edited by Peter Tommasini; 05-15-2015 at 01:59 AM. |

|

#3

|

|||

|

|||

|

Thanks very much for your advice Peter.

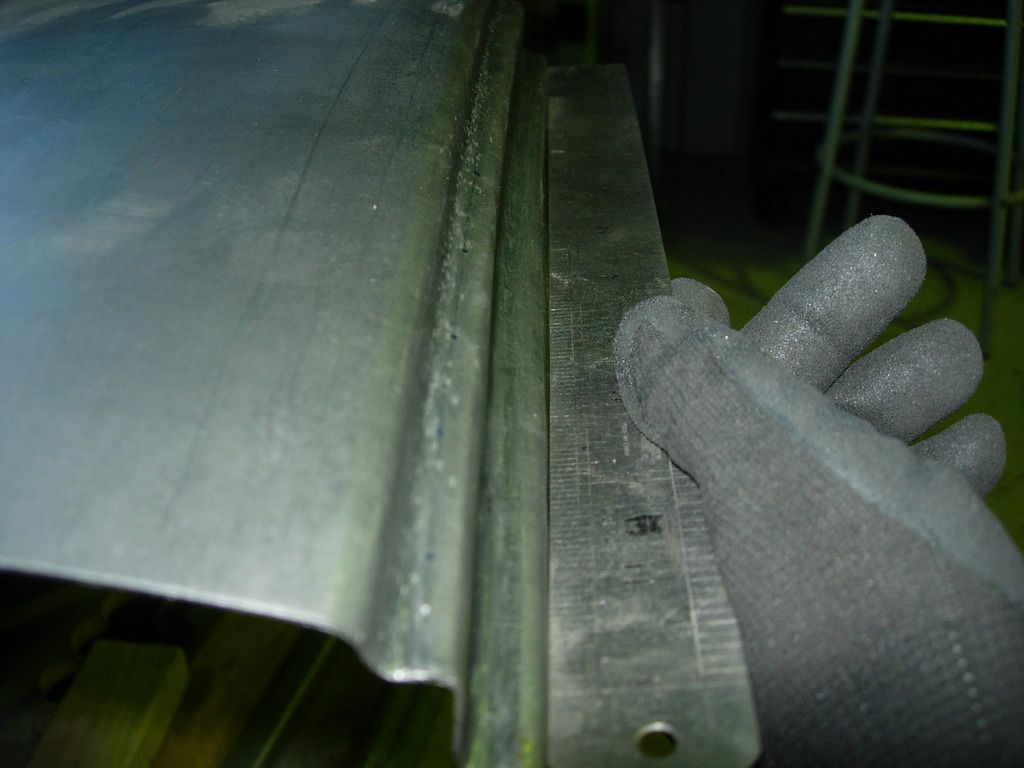

I attempted to make the panel today. I folded the first (outer) line over using the English wheel and it took all the shape out and I was left with a flat 90 degree fold. Unfortunately I couldn't get it into position on the English wheel to do the next fold. So I shrank the panel to the correct profile.  Then I made a die for the Trumpf and had a go at pressing the remaining lines in. It sucked itself in on the last fold line (inner) yet the panel matches fine with the door. So one direction is fine yet the other not so good. Unfortunately I don't know how to correct it. Perhaps I should be doing each line individually on the Trumpf/Pullmax??

__________________

Nigel.M |

|

#4

|

|||

|

|||

|

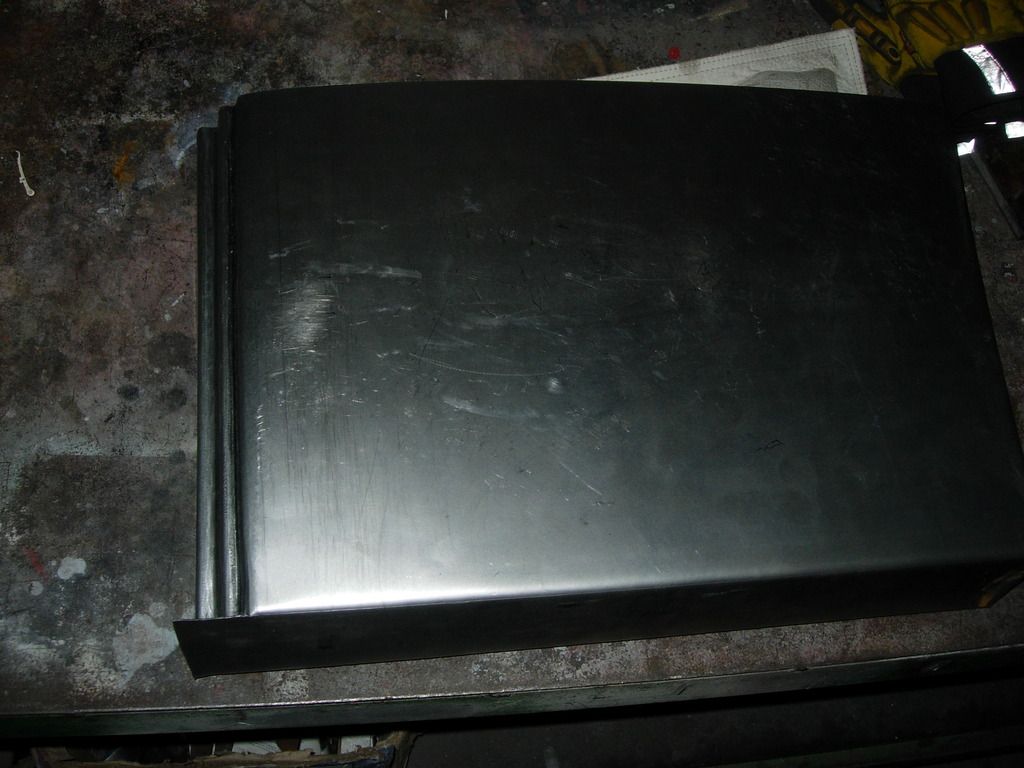

Got them in, thanks for your help Peter.

__________________

Nigel.M |

|

#5

|

|||

|

|||

|

nice work nigel. those double steps can be rough.

__________________

Steve |

|

#6

|

|||

|

|||

|

How did you get the sucked in section out?

__________________

Rex |

|

#7

|

|||

|

|||

|

I used the hammer and dolly on the inner most step to stretch it a bit.

__________________

Nigel.M |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|