|

|

|

#1

|

|||

|

|||

|

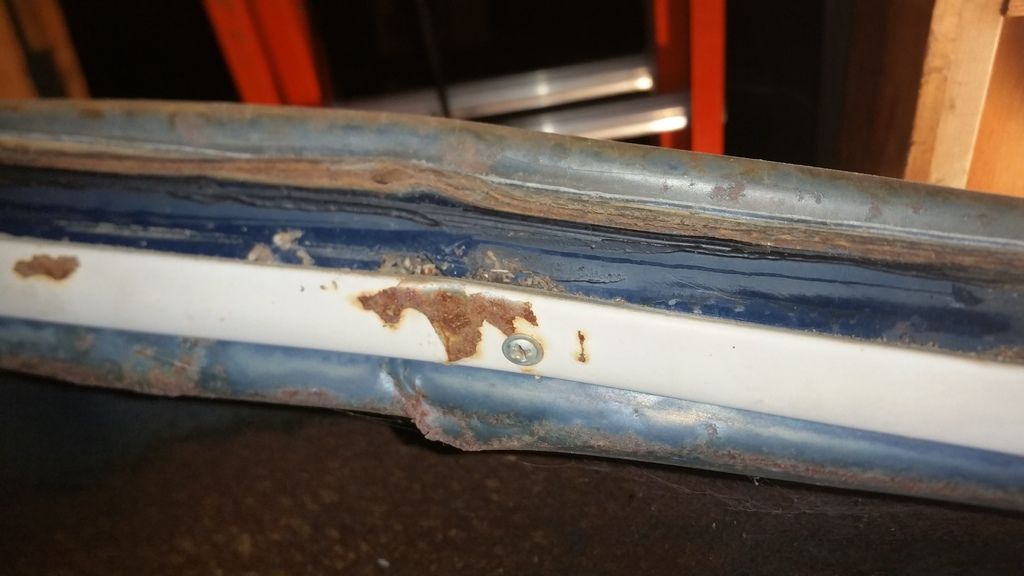

I finally got around to removing the windshield gaskets from the 1952 Studebaker truck cab I picked up as a replacement for a severely rusted original. Well, I found some damage I'm not sure how to fix or if it is possible. There's a dent in the opening that has pushed up and wrinkled the opening on the drivers side. Please take a look and give me any thoughts you have! The white part with the screw going through it is trim.

__________________

Kyle Carlsten, Faribault Minnesota |

|

#2

|

||||

|

||||

|

A pair of Vise Grips with a slide hammer should bring that back into place.

Move slowly and keep control of it. Jere

__________________

Jere Kirkpatrick Valley Forge & Welding HEN-ROB Torch Dealer.  Teaching The Fundamentals of Metal Shaping www.jerekirkpatrick.com All tools are a hammer except the chisel.....That's a screwdriver. |

|

#3

|

|||

|

|||

|

I thought, yes, run a thin cutting disc through there, tap the shape back then close it with the TIG before finishing. Then Jere said use a pair of Vise Grips and a slide hammer and I thought, why didn't I think of that? And that is why this is such a great forum.

Will

__________________

Here to learn. William Pointer |

|

#4

|

|||

|

|||

|

Somtimes it helps to drill out some spot welds, make two cuts and remove a section of the inside panel, then after pulling/straightening the opening, fit the inner part and weld it in. Also check the opening with the glass as you work, the roof may be "off " across more of the top.

__________________

John |

|

#5

|

|||

|

|||

|

The top suggestions are good ..but it might make more work for you, and the vise clips might not be strong enough they would probably slip out.

In my opinion.... you would need.....1 chain and turned buckle + clamps........ 2 clamps connected together by a chain at the bottom lip fairly wide apart (more space area) and one clamp on the top lip, connected the turned buckle from the top clamp on to the middle of the chain at the bottom and start winding  while the pressure is on ...be sure to tap down the high spot in the middle of the roof,......also make sure that the top clamp is much smaller than the bottom ones in order to pull right on the kink, if the top clamp take to much area it will not work properly, if you have not enough clamps,..... then just weld a small steel tag on the top lip ( PS ) if you have a push and pull porto power well ...you are in business Peter

__________________

P.Tommasini Metalshaping tools and dvds www.handbuilt.net.au Metalshaping clip on youtube http://www.youtube.com/watch?v=WEAh91hodPg Making Monaro Quarter panel: http://www.youtube.com/watch?v=KIpOhz0uGRM Last edited by Peter Tommasini; 12-17-2015 at 07:26 AM. |

|

#6

|

||||

|

||||

|

As Peter said above.

I deal with this type of collision damage frequently at work. Use a clamp on the pinch weld and a come along pulling forward and down. You can planish as you move the metal and while keeping tension on the come along. I also have a tool I made by welding a pair of vice grips to a nut that threads onto my slide hammer that would work for finishing but wouldn't grip well enough to pull the initial damage. It's not as bad as you think.

__________________

Jack Set a Goal So Big That You Can't Achieve It Until You Grow Into The Person That Can. |

|

#7

|

|||

|

|||

|

Thanks everyone! I have to admit, I panicked when I found this, I've already put a hundred or so hours into this body (5 for a skilled professional, haha) and I don't have the money for another one! I appreciate the advise and will be gathering the tools I'll need to fix it and keep working on the other items knowing this can be handled when needed. It's been more fun working on this truck this summer than in a long time, learned to be more patient and figuring stuff out. Had to remake the purchased floor pan and fabricate other patches over and over, but that's how I learn. I still weld poorly using my Flux core mig welder but even that's getting better.

Kyle

__________________

Kyle Carlsten, Faribault Minnesota |

|

#8

|

||||

|

||||

|

You will do even better if you ditch the flux core and run it with gas! You are making it way to hard on yourself.

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. |

|

#9

|

|||

|

|||

|

Quote:

Kyle

__________________

Kyle Carlsten, Faribault Minnesota |

|

#10

|

|||

|

|||

|

[QUOTE ] 1 chain and turnbuckle + clamps........

2 clamps connected together by a chain at the bottom lip fairly wide apart (more space area) and one clamp on the top lip, connected the turned buckle from the top clamp on to the middle of the chain at the bottom and start winding  while the pressure is on ...be sure to tap down the high spot in the middle of the roof,......also make sure that the top clamp is much smaller than the bottom ones in order to pull right on the kink, if the top clamp take to much area it will not work properly, if you have not enough clamps,..... then just weld a small steel tag on the top lip [/QUOTE] I'd go with Peter's method - but I break up an old mill bastard into 1.5inch chunks and use them to clamp on with, as the teeth grip really well. And, as you pull it down, as Peter says, be sure to hammer the high section on the roof to follow - although I lay a slapper on the skin and hit that to 1 spread the force and 2 to avoid leaving little "Kyle marks" --  Sometimes a dab of soft heat can help - if the Faribault temps are below 30F - don't heat for color, just for helping the move - but don't heat the clamp areas!!! "Go slowly and observe carefully."

__________________

Kent http://www.tinmantech.com "All it takes is a little practical experience to blow the he!! out of a perfectly good theory." --- Lloyd Rosenquist, charter member AWS, 1919. |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|