|

|

|

#1

|

||||

|

||||

|

Sorry for the lack of posts on shop projects, we've been cleaning the shop for the 2016 MD Tommasini Metalshaping Class. Here is a new sand bag we made up for the class, made from a full cow hide, it measures 40" x 24" x 4" high. We had some loose leather left over, so the top was wrapped to provide additional protection from any sharp metal... This uses just over four 5 gallon buckets of saved blast media to fill the bag, so we don't need any holes letting all that pour out on the floor!

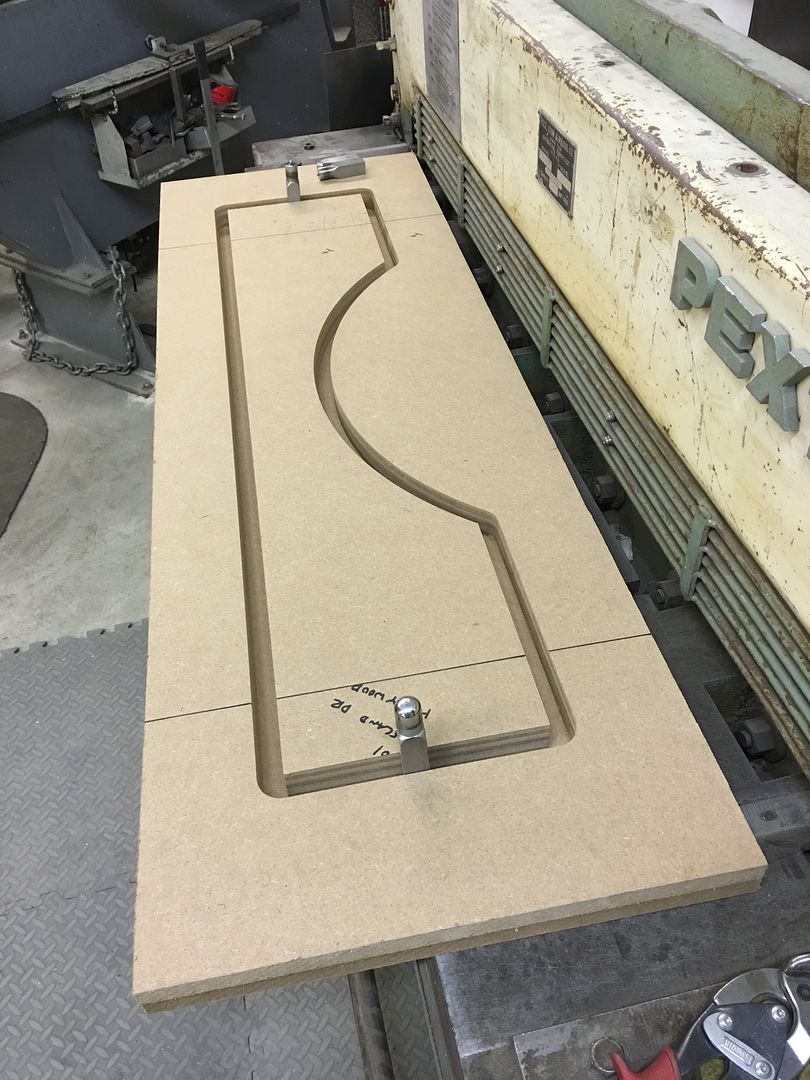

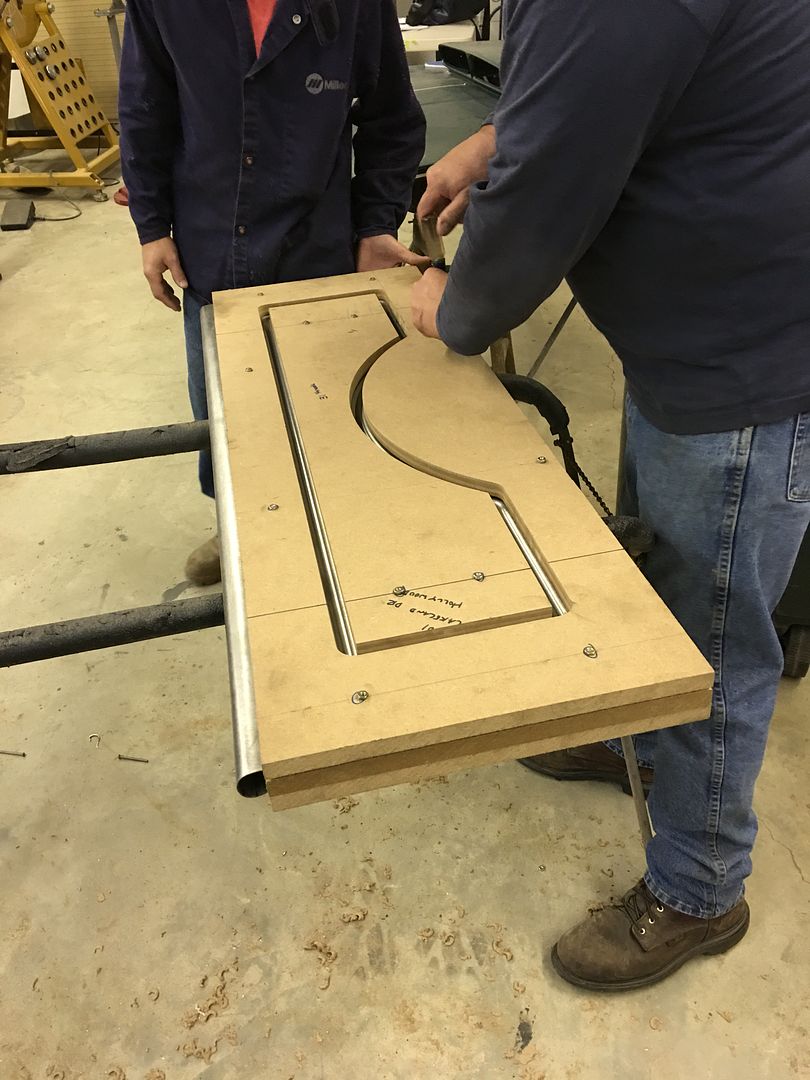

Some of the projects include duplicating these repro BMW saddlebags in aluminum, and this Mopar hood in aluminum......   Here Peter shows using the stump for tuck shrinking  Here Peter modifies the heel of a ball peen hammer for less marking while tuck shrinking...  Here it is in use.... https://www.youtube.com/watch?v=plpfX1aPAI0 Duplicating the hood....    A local source was used to CNC a template for bead detail on some Model A p/u bedsides....  Bead added....  Motion picture version: https://www.youtube.com/watch?v=CSD_RUh6bMg  Close-ups of the results...   1937 Dodge coupe door repairs... the lower inner and lower door skins are fabricated...   A complex architectural piece that was shrunk, stretched, planished, and reverses added, all with the same hammer...   Saddle bags in process... https://www.youtube.com/watch?v=Fnapwrq0lzw after wheeling...  Some other efforts of shrinking, blocking, and planishing in making a fender profile and rear corner of a T-bucket in aluminum...    Two days in the books, two to go!

__________________

Robert Instagram @ mccartney_paint_and_custom McCartney Paint and Custom YouTube channel |

|

#2

|

||||

|

||||

|

Wow, a lot of productivity going on so far!

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. |

|

#3

|

|||

|

|||

|

WOW! Really neat stuff that you guys are working on. Robert you sure have a well equipped shop. Nice and neat and clean as well. Do you still have that flexible shape pattern in your shop? I know Peter is fond of that metal shaping 'tool'

__________________

Will |

|

#4

|

|||

|

|||

|

. Do you still have that flexible shape pattern in your shop? I know Peter is fond of that metal shaping 'tool'

Yea ....     :rolle yes: :rolle yes:  love the stuff, really accurate, can not make a panel with out it!!!! love the stuff, really accurate, can not make a panel with out it!!!!       Peter

__________________

P.Tommasini Metalshaping tools and dvds www.handbuilt.net.au Metalshaping clip on youtube http://www.youtube.com/watch?v=WEAh91hodPg Making Monaro Quarter panel: http://www.youtube.com/watch?v=KIpOhz0uGRM |

|

#5

|

|||

|

|||

|

Looks like plenty of learning was going on that week end..

__________________

John EK Holden V8 |

|

#6

|

|||

|

|||

|

All kinds of different styles & techniques, that must have been quite a time. Wish I had made it.

__________________

oj higgins |

|

#7

|

||||

|

||||

|

Thanks guys! OJ, Thetan was a real hoot. Would love to work with him on a project or two..

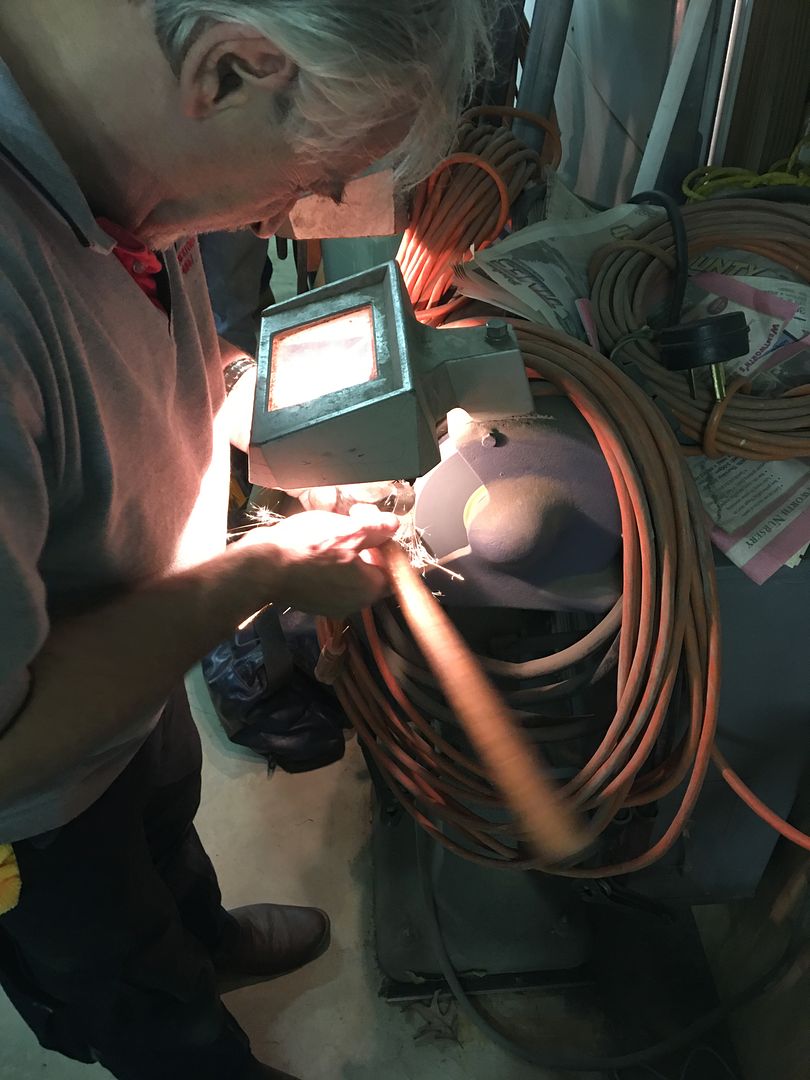

The final two days of the Maryland Tommasini Metalshaping Class. We had two stumps that we gave to students to take home, here is the final version carved.... https://www.youtube.com/watch?v=5yH-M21yUok I had some requests to show the mammoth sand bag with the loose cover removed... It saw quite a bit of use and came in handy!  More repair parts were made for the 37 Dodge doors...       The crease or "swage" at the top center of the hood was difficult to locate through the paper pattern.  So the upper and lower "crease" was highlighted by using fineline tape alongside. Then a pencil was used on the outside of the paper pattern, which now showed the location. Better shown here: https://www.youtube.com/watch?v=miZW1aOWwXg The halves still need to be welded together using O/A. Two of the ball glove pounding pads were put into service for metalshaping, one using shot, the other using sand..  Peter showed lead loading method for aluminum...

__________________

Robert Instagram @ mccartney_paint_and_custom McCartney Paint and Custom YouTube channel |

|

#8

|

|||

|

|||

|

Huh, Peter must have been doing that aluminum leading lesson while I was sleeping at Will's..... Seriously, I am curious- does the leading process involve enough heat to anneal the aluminum and thus require any additional steps?

Thanks for posting great pics and video links. The hood process & details mentioned, thin line tape, etc. are relevant to a project I have here. It's very much on the back burner, but at least now I have a better strategy if it progresses.

__________________

AC Button II http://CarolinaSculptureStudio.com https://www.youtube.com/channel/UCzSYaYdis55gE-vqifzjA6A Carolina Sculpture Studio Channel |

|

#9

|

||||

|

||||

|

I guess I must have been sleeping.... I did not know that you could lead aluminum. I'd like to know more. Is that covered in one of Peter's DVDs and, if so, which one.

If this has been discussed here before, I must have missed it.

__________________

Kerry Pinkerton |

|

#10

|

|||

|

|||

|

Peter demonstrated this process last year at the Colorado class. The bond is very strong. The piece can be bent and it all stays together. From what I remember the process is very similar to leading steel.

__________________

Bob Don't believe everything you think. |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|