|

|

|

#1

|

|||

|

|||

|

I thought I would start a new thread to show the work we did in making a new set of wings (fenders) making a new petrol tank and cladding the body of an original 1937 SS100.

The car has some race history but has not been on the road for many years. I will go into more details later but to outline the project we were given an ash frame which had been 'restored', this was mounted on the original rolling chassis. We also had a set of original wings and part of an original petrol tank to work from. Looking around the ash frame it was soon evident that it was in need of quite a bit of work to make it usable.  Above James starts to rectify some of the problems we found. David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. |

|

#2

|

||||

|

||||

|

I'm looking forward to it!

__________________

Rick Scott The second mouse gets the cheese! |

|

#3

|

||||

|

||||

|

Cool project. Can't wait.

Frank

__________________

Frank de Kleuver |

|

#4

|

|||

|

|||

|

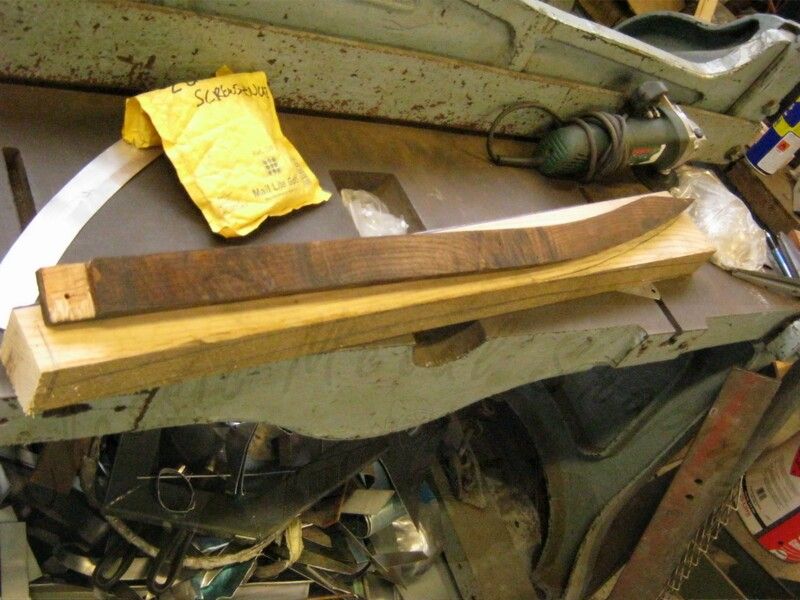

The ash frame had been given at some time, to someone who was supposed to restore it in exchange for being allowed to copy it. I guess you get what you pay for. I wish we had got it before it had been got at. One part that had been replaced was the rocker piece below the door, unfortunately the guy used a piece at ash with a great big knot in it and it was weak and would have been in danger of breaking, either when it was drilled for the wing bolts or when the ally was nailed on or at some point down the line.

Ash was used for making these frames because it is strong and light and also because it goes not have many knots! In the photo above the old section is placed on the new piece of timber used to replace it. David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. |

|

#5

|

|||

|

|||

|

The new rocker piece James made and fitted...

Notice that there are no knots in it!. There were lots of little chips taken out of the frame when the skin was removed. This is a problem because the skin is formed around the wood so any imperfections would transfer through and show in the finished job. We put new pieces of ash into the frame to give us something solid to work on. Thanks to modern adhesives the repairs are strong.  It would have been better for the skin to have been remove with more care. David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. Last edited by David Gardiner; 08-13-2013 at 05:37 PM. |

|

#6

|

|||

|

|||

|

There were areas like this...

where the wood should have been replaced, this is another area where the skin is wrapped over and nailed, there would give been nothing to nail to. New wood was put in to replace the old.  David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. |

|

#7

|

||||

|

||||

|

Looks like your having Fun David!

__________________

Brent Click |

|

#8

|

||||

|

||||

|

My dad is a carpenter and would love this stuff. I'll show him asap. He would want me to build a Morgan just for the wooden superstructure alone ;-)

Grt Frank

__________________

Frank de Kleuver |

|

#9

|

|||

|

|||

|

If I may ask, what modern adhesive do you use for this repair work?

__________________

Bob |

|

#10

|

|||

|

|||

|

Brent, It was OK doing this part but not do good when we discovered that the rear of the frame was totally ot if square.

Quote:

David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|