|

|

|

#651

|

||||

|

||||

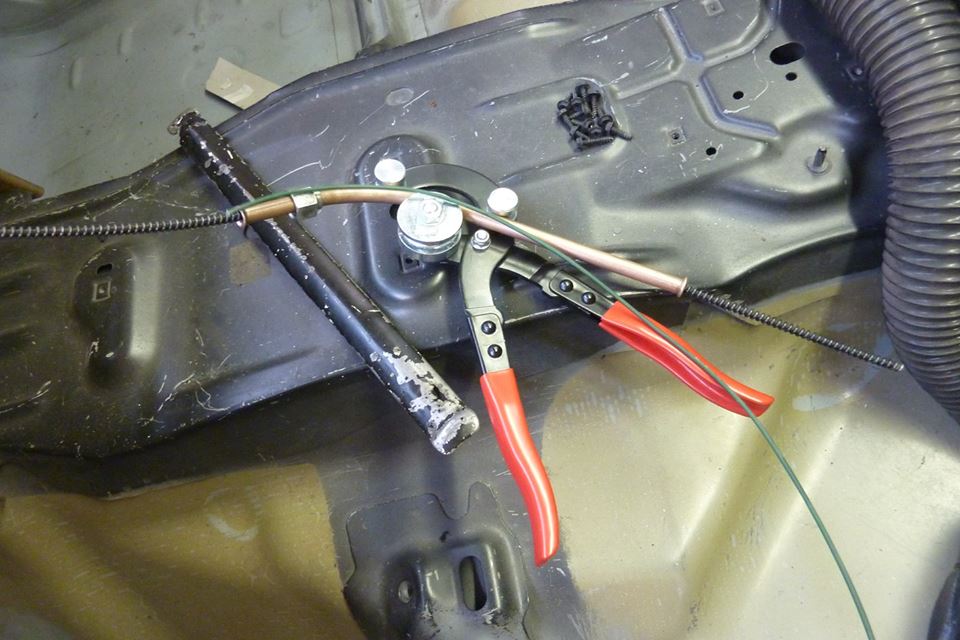

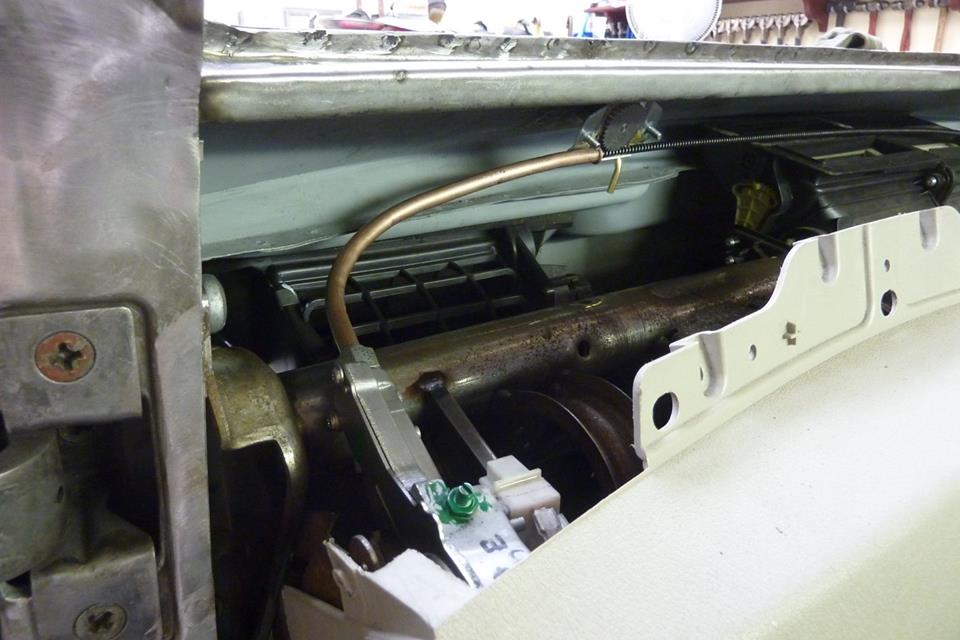

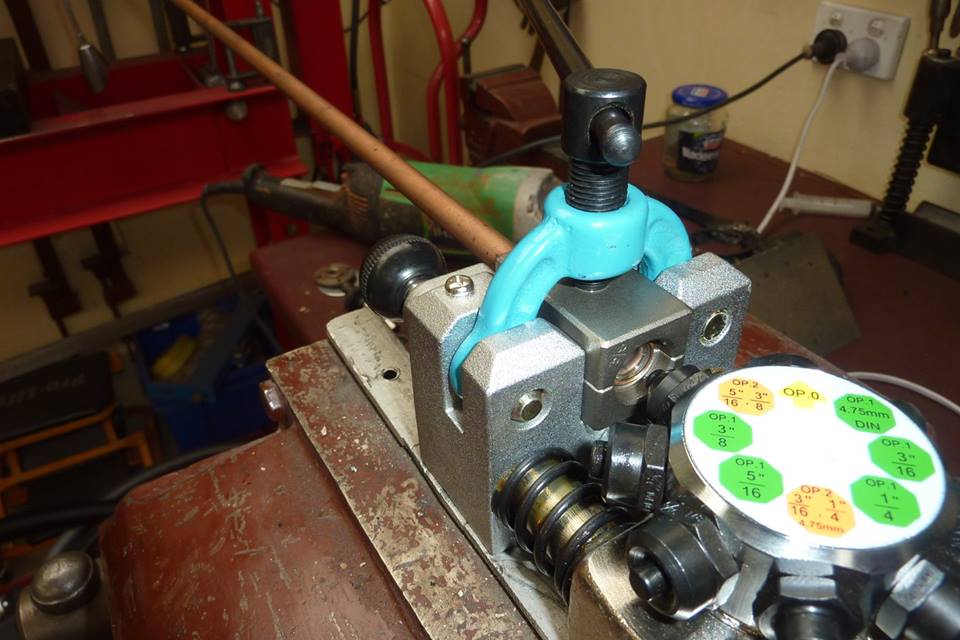

Just thought I would show how this system works. The rack consists of a cable with a spring wrapped around it. The spring engages the teeth on the wheelbox, or wiper pivot. The motor as a crank that pulls the rack back and forth giving you the movement.  These wheelboxes not only come in different overall lengths, but also in the number of teeth they have. This classic Mini one has 32 teeth but the older Minis had only 24 teeth which would give more sweep of the wiper arm. Some even have 40 teeth which would decrease the sweep. Some Jags even have a different number of teeth one one side to the other to vary the sweep left compared to right side. The sweep can also be changed with different stroke lengths by where the pivot on the wiper drive gear. Can buy different ones from 90 to 150 degrees in 5 degree steps mostly. Can also modify it yourself to whatever you need.  The rack runs inside tubing and made mine from scratch. What is used is 3/8" bungy tubing which is usually a mix of steel and aluminium like used for brake and fuel lines often. I have a steel/copper mix which what I could get locally that will work just as well. Straight steel wears the rack too quickly and straight copper the rack wears the tubing too fast. The bend radius should never be less than 3" for the rack to work smoothly. A good idea to leave the rack inside the tubing while bending it to help stop kinking as you cannot have that.  I tried to make the bend as shallow as possible to reduce wear and noise.  I use this Eastwoods tubing flarer. I works so quick and well that I wish I had one when I used to work as a brake mechanic long time ago. The first step makes the tubing flush at the end of the die.  Rotate the head and Step 2 makes the ball at the end of the tubing just by pulling the handle around once.  Last step inverts the flare so you end up with a double wall thickness at the end of the tubing. Some people just do a single flare when building their wiper racks.  And there is your perfect flare. I make sure the tubing in square to begin with and any burrs removed. Lube it with brake fluid if for a car, but just used some lanolin for this.  A bit of time is taken to get the tubing to sit in the wheelbox housing flat so it doesn't pull the wheelbox out of alignment left to right.  Nice that this side the rack comes into the top of the wheelbox rather than the bottom like the otherside. This is so the movement goes in the opposite direction for the folding arms or clapped hands style.  I bent the tubing to go behind the front vent outlets on the air-conditioning unit.

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. Last edited by Gojeep; 08-14-2017 at 03:52 AM. |

|

#652

|

|||

|

|||

|

Truly amazing! The wiper solution is very slick. One of my favorite reads!

__________________

Larry |

|

#653

|

||||

|

||||

|

Nice wiper installation! Details!

__________________

Robert Instagram @ mccartney_paint_and_custom McCartney Paint and Custom YouTube channel |

|

#654

|

||||

|

||||

|

Quote:

Well then, she is DEFINITELY a keeper!

__________________

Kerry Pinkerton |

|

#655

|

||||

|

||||

|

X2.

It is good, but after reading all the comments about Import failures, I'm now worried about my aftermarket set.  I already bought it and it can't be sent back. I already bought it and it can't be sent back.I will put some real consideration into chasing better parts now. Thanks. |

|

#656

|

||||

|

||||

|

Ha ha, that she is. She is the one that got me this Willys in the first place as well!

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. |

|

#657

|

||||

|

||||

|

Even the EZ wire one which I was going to buy has a lot of problem of being noisy and wearing out quickly. Best aftermarket one the US made Specialty Power kit. Was just too expensive once I added up all the costs for mine though once freight was added.

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. |

|

#658

|

|||

|

|||

|

Damm, this is so amazing!

Thanks for sharing, a lott to learn here. Keep up the good work!

__________________

Ivar Pieper |

|

#659

|

||||

|

||||

|

Many thanks Ivar and welcome to the forum.

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. |

|

#660

|

||||

|

||||

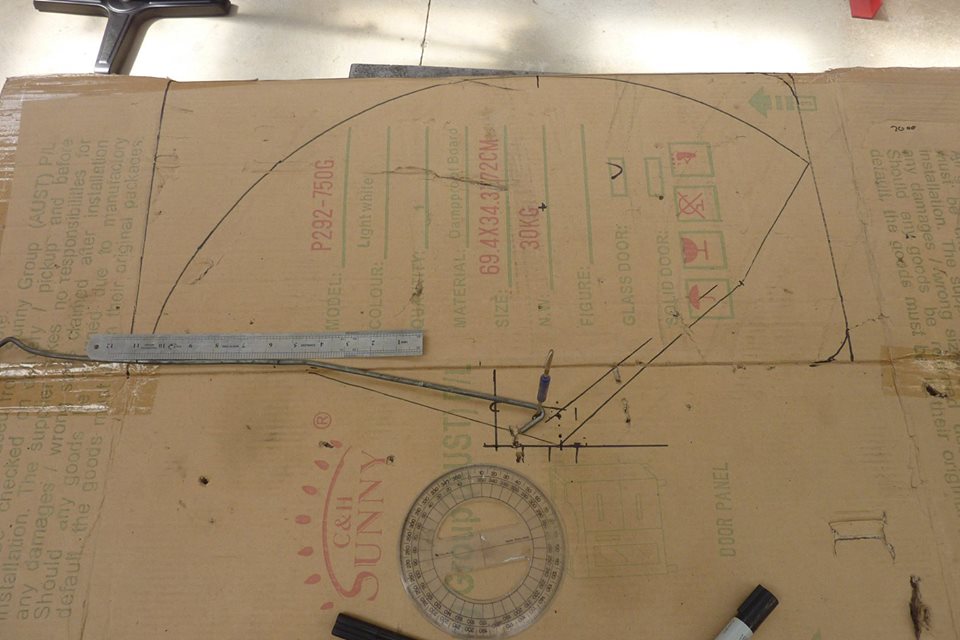

Here is the frame work the motor sits in behind the dash.  Found the picture of my 'CAD' layout of the possible wiper pivot points and arm lengths verses blade length testing. Drew up one side of the split screen glass area, not including the rubber gasket, to see the influences of each different setup. Can work out degrees of sweep this way too. Then see what best fits the situation and what is available.  This is the donor Jeep ducting that goes from the centre of the A/C unit to the side of the dash by the door. The ducting does not fit under my sloping cowl however so can't use it as is.  Spent an afternoon at the local pick-a-part yard to find suitable tubing and fittings etc for the vents system. Not much available now a days as most cars have it in moulded in under the dash. Most of this was from older Range Rovers and Mercedes cars from the 70-80's  I cut the end off the Jeep ducting that holds the grille part in in place. The shape was going to be hard to join round ducting too.  So using a heat gun over one of my T stakes, I reshaped it. Once it got soft I pushed the folds flatter with some flat steel.  Used one of the elbows from a Mercedes and cut most of the square end off so it would fit inside.  It was a bit bigger in diameter, so cut a wedge out to reduce its circumference.  Put a hose clamp around it once it was in the right position.  Then using a soldering iron welded the seam back up. Been a while since I had welded some plastic as used to do a bit now and again back in the 80's before Youtube was around to show you how!   Welded all the way around and even inside to make a good strong connection. I used a 80 watt soldering iron as was thick, but normally only use a 40 watt one. Don't want it too hot as leaves it brittle when it starts smoking a lot. Always have a fan going as the fumes are toxic.  This gives you an idea of where it sits when screwed in the end of the dash.  Got both sides done now and will use the original ducting from the Mercedes as well which was a bit over 66mm-2.5".  It will hook around in front of the defrost vent and go to the front most outlets at the top of the A/C unit.

__________________

Marcus aka. Gojeep Victoria, Australia http://willyshotrod.com Invention is a combination of brains and materials. The more brains you use, the less materials you need. Last edited by Gojeep; 08-14-2017 at 03:57 AM. |

|

| Thread Tools | Search this Thread |

| Display Modes | |

|

|